Bottom price Industrial Dry Vacuum Cleaner - FB series three phase Explosion-proof Vacuum cleaner – Marcospa

Bottom price Industrial Dry Vacuum Cleaner - FB series three phase Explosion-proof Vacuum cleaner – Marcospa Detail:

The feature is more safety and explosion-proof , lighter and more affordable than other heavy industrial vacuum cleaners. It is suitable for continuous operation of explosion-proof areas and flammable and explosive dust or industrial equipment. Widely used in metal processing, plastic sheet processing, battery, casting, electronics, 3D printing and other industries.

Parameters of this wholesale FB series three phase Explosion-proof Vacuum cleaner manufacturer

| Model | FB-22 | FB-40 |

| Power(Kw) | 2.2 | 4 |

| Voltage(V/Hz) | 380/50~60 | |

| Airflow(m3/h) | 265 | 318 |

| Vacuum(mbar) | 240 | 290 |

| Tank volume(L) | 60 | |

| Noise dB(A) | 72±2 | 74±2 |

| Inhalation diameter(mm) | 50 | |

| Filter area(m2) | 3.5 | |

| Filter capacity | Anti-static filter(0.3μm>99.5%) | |

| Filter cleaning | manually rotate | |

| Dimension(mm) | 1220*565*1270 | |

| Weight(kg) | 105 | 135 |

Pictures of this wholesale FB series three phase Explosion-proof Vacuum cleaner supplier

Feature

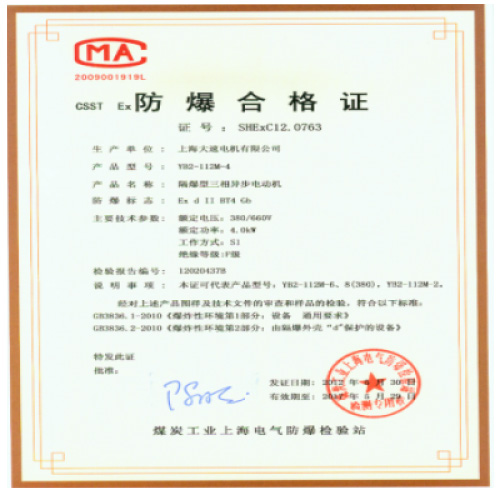

1. Explosion-proof motor ,prevent motor electrical spark

The power system adopts the international advanced explosion-proof precision casting turbine fan (air pump), wide-voltage dual-frequency, high reliability, low noise, long life and continuous operation for 24 hours. Power is available from 0.25kw to 4.0kw, power supply is 380V / 50Hz.

explosion-proof grade of motor:Ex d Ⅱ BT4 Gb

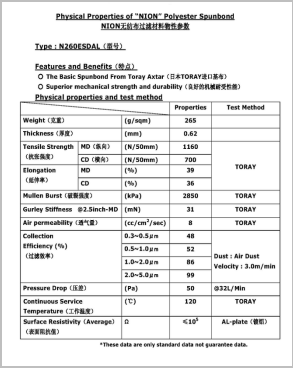

2. Anti-static filter to prevent static spark hazards

Optional star bag and cartridge filter for filtration systems.

The star bag filter uses an antistatic blended felt to enhance conductivity by adding binary fibers.

The filter cartridge filter is treated with aluminized surface coating, which has good antistatic performance and surface resistance ≤105&Omega

3. Explosion-proof electric box to prevent electric spark hazards

The control system adopts explosion-proof electric box, internal AC contactor and thermal overload use Schneider electrical components.

Explosion-proof electric box, explosion-proof mark: Ex d II BT4

4. Negative pressure monitoring, cleaning reminder

The negative pressure gauge is the standard configuration component of the whole machine. It is specially designed for industrial vacuum cleaners by Puhua. The green, blue and red respectively correspond to the internal negative pressure of the machine in each power section. The pointer points to the red area to represent the filter needs to be cleaned or replaced.

5. Industrial casters, easy to move

Industrial caster is easy to install. The wheels are made of top-grade polyurethane (PU), the brackets are made of 2.5mm pickling plates to increase the ribs, and the 2-inch casters can carry 50kg individually. The wheel surface is designed with grain to enhance the anti-slip performance.

6. Separate the upper and lower barrels, easy to clean

The upper and lower barrel separation structure is the standard configuration of the machine, which brings the greatest convenience to the user. It is convenient to clean the dust. When it is necessary to clean the dust, only to need lift the pressure bar, the dust collecting barrel naturally falls to the ground, and move the barrel.,dump the dust, and press the pressure bar after finishing.

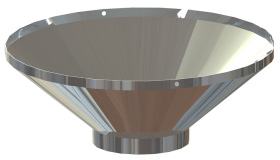

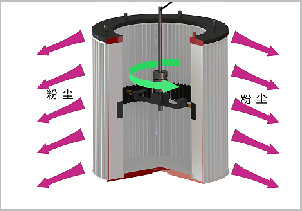

7. Cyclone inside to reduce the load on the filter

The internal cyclone structure is the standard configuration of the machine. It is installed at the connection with the suction port. Large particles can be directly settled under the dust collecting bucket through the cyclone separator. It does not need to be intercepted and trapped by the filter, which can increase the life of the filter.

8. Anti-static interface and hose

The hose and connector are made of anti-static material, the electrical conductivity is in accordance with DIN53482, and the surface resistance is <106&Omega

9. The filter adopt manually rotate to clean the dust, which is convenient and efficient.

Rotating dust cleaning adopts the manual mode. You only need to rotate the rotating handle clockwise/counterclockwise for about 1 minute to clean the large particles of dust adhering to the surface of the filter.

Product detail pictures:

Related Product Guide:

Our merchandise are commonly recognized and reliable by customers and can meet constantly developing economic and social desires for Bottom price Industrial Dry Vacuum Cleaner - FB series three phase Explosion-proof Vacuum cleaner – Marcospa , The product will supply to all over the world, such as: Algeria, Juventus, Seychelles, we rely on own advantages to build a mutual-benefit commerce mechanism with our cooperative partners. As a result, we've gained a global sales network reaching the Middle East, Turkey, Malaysia and Vietnamese.

We have been engaged in this industry for many years, we appreciate the work attitude and production capacity of the company, this is a reputable and professional manufacturer.